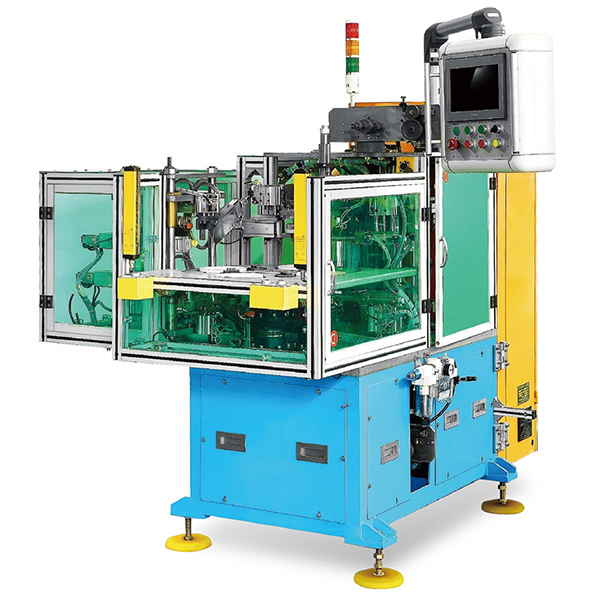

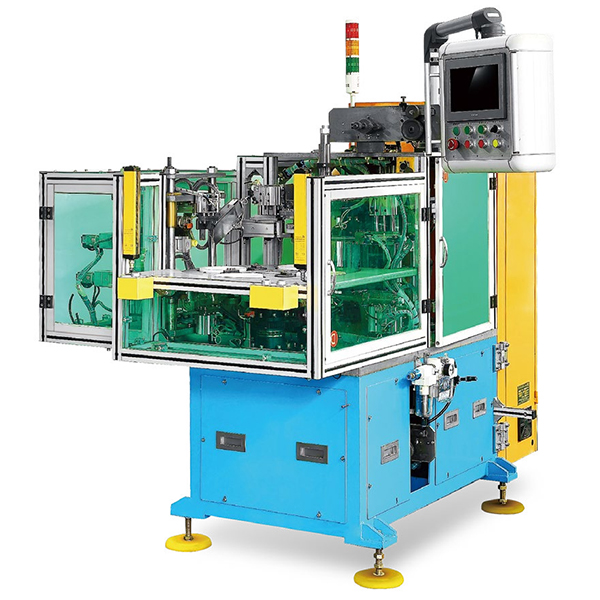

Four-Station Servo Double Binding Machine(Automatic Knotting And Automatic Processing Line Head)

Product Characteristics

● CNC9 axis CNC system of machining center is used to control and cooperate with man-machine interface. The function and stability of the binding machine can not be satisfied by all the existing PLC systems in the market.

● It has the characteristics of fast speed, high stability, accurate position and rapid die change.

● The machine is equipped with automatic adjusting stator height, stator positioning device, stator pressing device, automatic wire feeding device, automatic wire shearing device, automatic wire suction device and automatic wire breaking detection device.

● The four-station rotary working platform saves the time of putting the stator in automatic operation, thus greatly improving the overall efficiency.

● This machine is especially suitable for refrigerator compressor motor, air conditioning compressor motor stator wire binding, and such short lead motor production line automation.

● This machine is also equipped with automatic hook tail line device, which has the functions of automatic knotting, automatic tightening, automatic cutting and automatic suction.

● The unique patented design of double-track cam is adopted. It does not hook and turn slot paper, damage copper wire, no hair, no missing binding, no damage to tie wire and no crossing of tie wire.

● Automatic refueling system control can ensure the quality of equipment even more.

● Hand wheel precision adjuster is easy to debug and humanized.

● Reasonable design of mechanical structure and correct use of various high-performance steel, copper, aluminum and other materials make the equipment run faster, have lower noise, have longer service life, and have more stable performance.

Product Parameter

| Product number | LBX-03 |

| Number of working heads | 1PCS |

| Operating station | 4 stations |

| Outer diameter of stator | ≤ 160mm |

| Stator inner diameter | ≥ 30mm |

| Transposition time | 0.5S |

| Adapt to the stator stack thickness | 25mm-155mm |

| Wire package height | 10mm-60mm |

| Lashing method | Slot by slot, slot by slot, fancy lashing |

| Lashing speed | 24 slots≤18S |

| Air pressure | 0.5-0.8MPA |

| Power supply | 380V three-phase four-wire system 50/60Hz |

| Power | 5kW |

| Weight | 1500kg |

| Dimensions | (L) 2100* (W) 1050* (H) 1900mm |

Structure

Safety specifications for the use of automatic wire binding machines

Modern machinery continues to contribute to production and manufacturing advancements in all industries. For example, automatic wire binding machines have revolutionized traditional production processes that require a lot of manpower. With this machine, labor costs are greatly reduced, resulting in greater profit margins. Widely used in the manufacture of various mechanical parts, such as generators, washing motors, refrigeration compressors, fan motors and other machinery.

There are inherent risks in using an automatic wire binding machine, especially when dealing with heavy machinery. Safety must be given top priority to prevent accidents or injuries. Here are some safety precautions to consider when using an automatic wire binding machine:

1. Before using the wire binding machine, prepare labor protection supplies, including gloves, goggles, protective clothing, etc.

2. Before starting work, evaluate the condition of the power and brake switches to ensure they are functioning properly.

3. Do not wear gloves when operating the machine, so as not to be caught and cause equipment damage.

4. If there is a mold problem, please avoid touching it with your hands, but shut down and check the machine.

5. After completing the task, remember to clean up the wire loading machine and put it back to the storage place.

Guangdong Zongqi Automation Co., Ltd. specializes in the production of cutting-edge motor manufacturing equipment. The main products are four-head and eight-station vertical winding machine, six-head and twelve-station vertical winding machine, wire embedding machine, wrapping integrated machine, binding integrated machine, rotor automatic line, shaping machine, vertical winding machine , Slot paper machine, wire binding machine, motor stator automatic line, single-phase motor production equipment, three-phase motor production equipment. Our company integrates R&D, manufacturing, sales and after-sales service to provide customers with an efficient marketing network. We look forward to working with you to achieve your business goals.