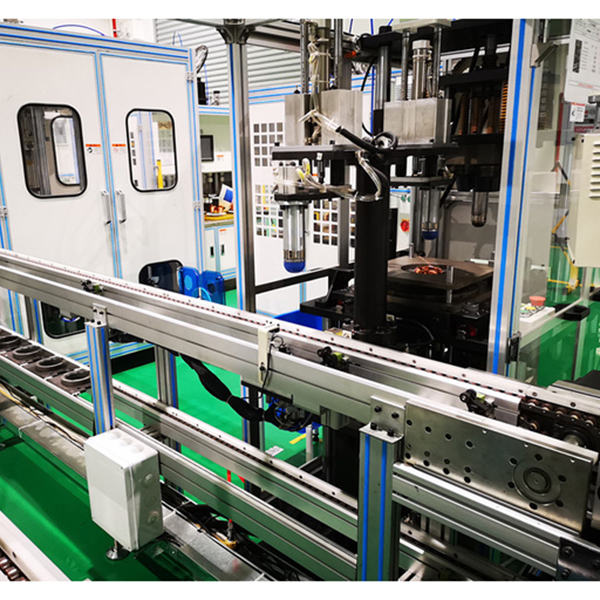

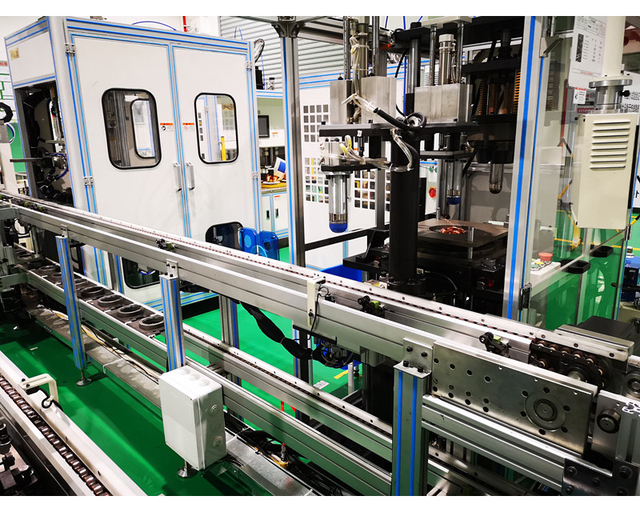

Stator automatic production line (double speed chain mode 2)

Product Description

The automatic production line transfers the tooling through the double-speed chain assembly line, (including paper insertion, winding, embedding, intermediate shaping, binding, finishing and other processes) with precise positioning and stable and reliable performance.

Structure

How to adjust the current of the rotor automatic line spot welding machine?

The rotor automatic line spot welder was originally equipped with an AC controller and an AC spot welder, but the unstable current of the AC spot welder and the problem of virtual welding caused it to be replaced by an intermediate frequency inverter DC controller, an intermediate frequency inverter, and a spot welder. In this article, we will discuss various methods of adjusting the current of the rotor automatic wire spot welder:

1. Constant power mode control: Using constant power mode Q=UI can avoid the rise of electrode resistivity and temperature when using constant current mode, and prevent thermal Q=I2Rt from rising. By using a certain power mode Q=UI, heat can become balanced.

2. Voltage measurement of two-rotor automatic line: voltage measurement should be carried out as close as possible to the positive and negative poles. The point is to control the voltage value between the positive and negative poles, not the voltage of the entire circuit.

3. Change from 1-pulse discharge to 2-pulse discharge or 3-pulse discharge (the total discharge time remains unchanged), and reduce the power value (or current value) to the minimum. If pulsed discharge is used, the power value will need to be increased to achieve the desired welding heat. If double-pulse discharge is used (the first pulse discharge value is set low, and the second pulse discharge value is set high), the power value (or current value) can be significantly reduced for welding. The reduction in power value (or current value) results in reduced electrode wear and improved welding stability. Q=I2Rt means that the accumulation of heat is more affected by the increase of current value. Therefore, when setting parameters, reduce the current value (or power value) to the minimum.

4. Replace the tungsten electrode on the hook under the spot welder with a negative electrode, because the current flows from the hook to the tungsten electrode, causing "electron movement", resulting in less metal atoms flowing to the electrode, making it dirty and exhausted. "Electronic motion" means that the flow of metal valence electrons causes the motion of a fluid body containing metal atoms.

According to the above method, the current adjustment of the rotor automatic wire spot welding machine can be successfully completed. This article aims to better understand the electromechanical uses of rotor automatic wire spot welders to improve production efficiency and save energy. In addition, frequent routine maintenance should be integrated into the operation of automatic rotor production lines. This contributes to its longevity and operational accuracy.