Guangdong Zongqi Automation Co., Ltd. boasts significant product advantages in the field of stator winding machines, which are directly reflected in various aspects of the machines. Below are the advantages of the company's integrated winding and insertion machines summarized by the company. When selecting a good integrated winding and insertion machine, we can consider the following aspects:

1. Product Functionality and Technical Features

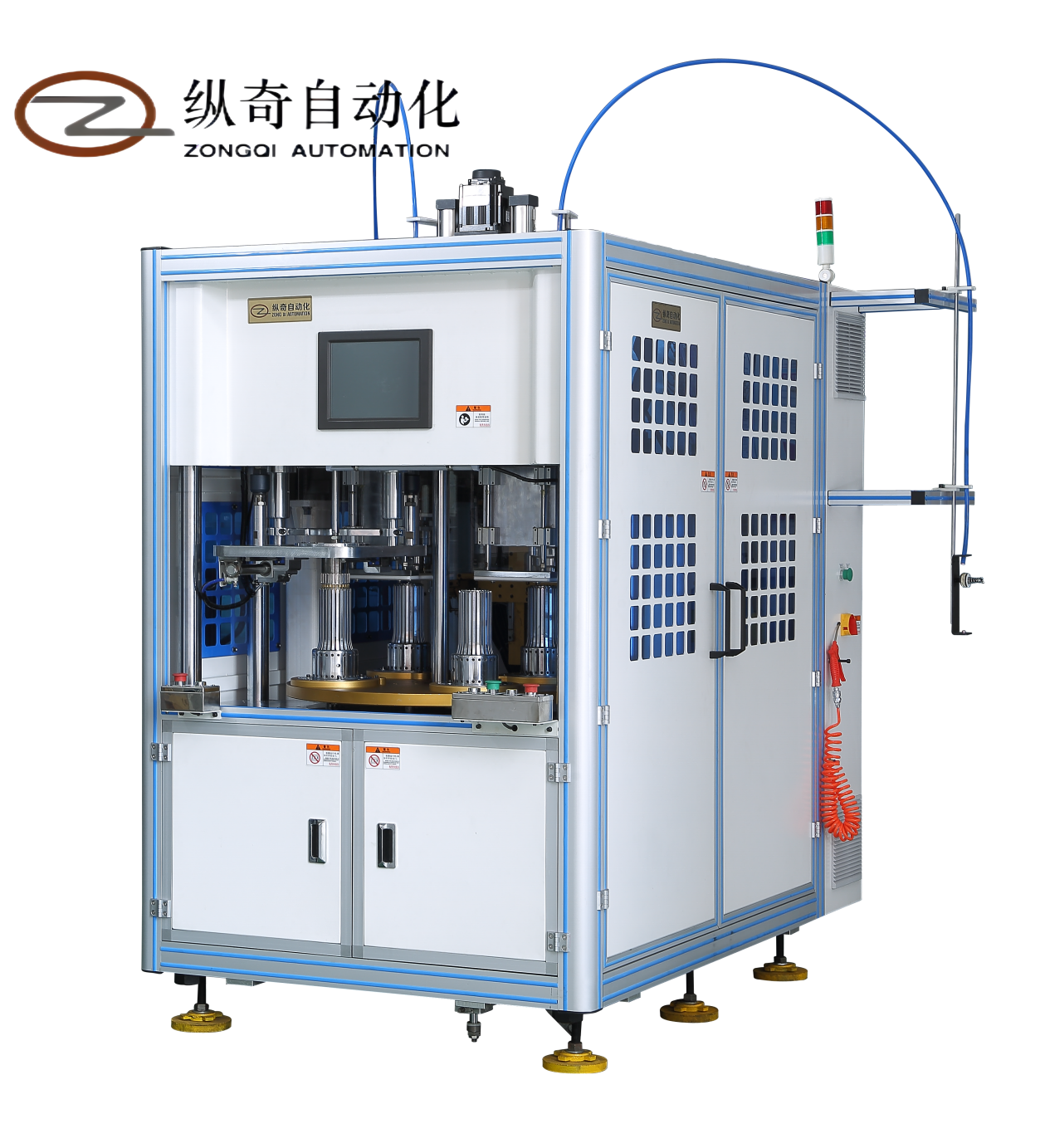

Automation Level: The integrated winding and insertion machines from Guangdong Zongqi Automation Co., Ltd. possess a high level of automation, including multiple workstations for automatic winding, insertion, and slot wedging, significantly enhancing production efficiency.

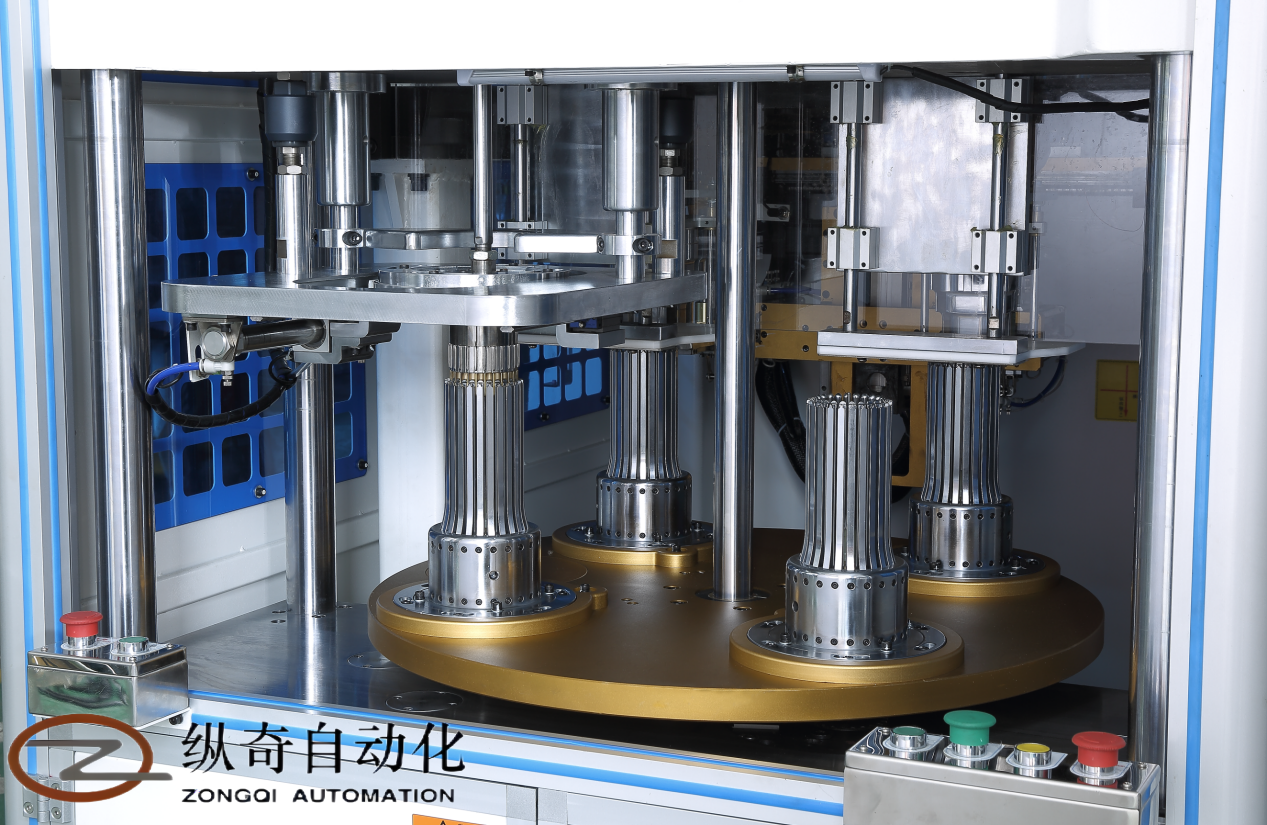

Precise Control: The machine is controlled by a precise cam divider (with a detection device after the end of rotation). The rotating diameter of the turntable is small, the structure is lightweight, the transposition is rapid, and the positioning is accurate, ensuring the accuracy and stability of the winding and insertion process.

Flexible Customization: Multi-head multi-position winding and insertion machines can be designed according to customer needs, meeting the winding and insertion requirements of different motors. Dual-power insertion or three sets of servo-independent insertion for high groove fill factor motors, as well as multi-head multi-position machines (such as one-winding one-insertion, two-winding two-insertion, three-winding one-insertion, four-winding two-insertion, and six-winding three-insertion) can be customized based on customer specifications.

2. Performance and Reliability

Low Energy Consumption, High Efficiency: The integrated winding and insertion machines feature low energy consumption and high production efficiency, helping enterprises reduce costs.

Low Noise, Long Lifespan: The equipment operates with low noise and has a long design life, reducing the frequency of maintenance and equipment replacement.

Ease of Maintenance: The equipment is designed with a reasonable structure, making it easy to maintain and service, further reducing the operating costs of enterprises.

3. Operation and Safety

Simplified Operation: Equipped with a 10-inch screen and supporting the MES network data acquisition system, the operation is made more convenient and intuitive.

High Safety: The machine boasts comprehensive safety protection mechanisms, such as paint film damage detection and alarm functions, as well as protective insulating paper devices, ensuring the safety of the operation process.

4. Adaptability and Expandability

Wide Adaptability: The equipment is suitable for various types of motors, such as fan motors, industrial three-phase motors, and water pump motors, demonstrating strong adaptability.

Strong Expandability: Functionalities or performance can be enhanced based on actual needs, meeting the evolving demands of enterprises.

In conclusion, when selecting a good integrated winding and insertion machine, attention should be paid to its automation level, performance and reliability, operation and safety, as well as adaptability and expandability. Guangdong Zongqi Automation Co., Ltd.'s integrated winding and insertion machines, with their advantages of high automation, precise control, flexible customization, low energy consumption, high efficiency, low noise, long lifespan, simplified operation, and high safety, have become preferred products in the market. Enterprises can make comprehensive considerations based on their actual needs and budgets when making a selection.

Post time: Jun-01-2024