Dear friends engaged in motor production around the world, we often get a common question: “We use high-quality core components for our motors, but why can’t we improve their performance? Issues like high noise, high energy consumption, and even frequent failures keep arising.”

In fact, the answer is simple: most of the time, the problem does not lie with the components themselves, but with the “detailed process” of stator winding. As the “heart” of a motor, the tightness, density, and regularity of the windings directly determine the motor’s power, energy consumption, and service life. Today, we’ll talk about how to optimize the stator winding process in the most straightforward way to improve motor performance at the lowest cost. We won’t use obscure terminology, so even beginners can easily understand.

First, let’s share a few practical, actionable optimization methods. You don’t need to make major changes to your production line; simple adjustments can deliver noticeable results.

First, properly control the winding tension—it’s the most basic and critical step. Many of you may overlook this: if the tension is too high, the enameled wire will be thinned, broken, or even have its insulation layer damaged, leading to short circuits during subsequent use. If the tension is too low, the wound wire will be loose with large gaps; when the motor operates, the wire turns will rub against each other, producing loud noise, affecting magnetic field stability, and directly increasing energy consumption.

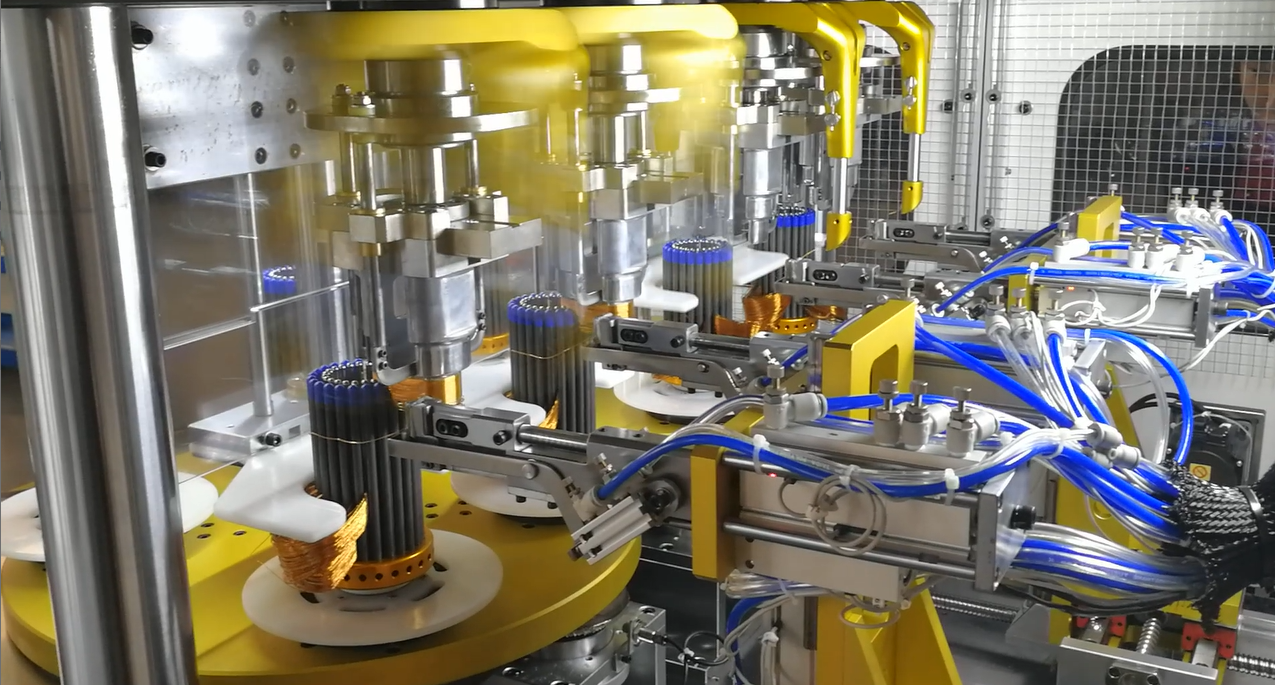

Here’s a simple way to judge: the wound wire turns should fit tightly into the stator slots—no looseness, no overlap, and no deformation when gently pressed by hand. That’s the optimal tension. If manual control is difficult, we recommend switching to an automatic winding machine with adaptive tension control. For example, our Zongqi equipment can monitor wire diameter and tension in real time, making automatic compensation and adjustments. You won’t need to keep a constant eye on it for corrections, saving both labor and hassle.

Second, optimize the winding arrangement to avoid wire “tangling.” In many traditional winding methods, wire turns cross and overlap, which not only wastes space in the stator slots but also affects magnetic field uniformity. An uneven magnetic field causes the motor to vibrate, produce loud noise, and deliver unstable power during operation. Especially now, as many motors require a high slot fill rate, it’s even more important to arrange the copper wires tightly and neatly.

Simply put, try to arrange the wire turns in parallel during winding, avoid crossing, and fill each layer neatly to maximize the use of stator slot space. For example, use high-speed flywheel winding for small motors and needle winding for large motors. Choosing the right winding method for your motor type increases the slot fill rate, which in turn improves the motor’s power density and reduces energy consumption. If using multi-wire parallel winding, ensure multiple wires are arranged synchronously without interference—this requires the equipment to have precise path planning capabilities to prevent collisions between the winding head and the stator.

Third, properly handle insulation after winding to avoid major losses from minor mistakes. The insulation layer after winding acts as the motor’s “protective coat.” Once damaged, short circuits will occur between wire turns, leading to immediate motor failure and even potential safety hazards. Many of you may skip proper insulation treatment to save time—either the insulation paper is not inserted correctly, or the dipping paint is incomplete— which often causes problems later on.

We recommend checking the insulation paper in the stator slots before winding to ensure it fully covers the slot walls without damage or misalignment. After winding, promptly perform dipping paint treatment to ensure the insulation paint evenly covers every wire turn and completely fills the gaps between them. This not only provides insulation but also secures the wire turns and reduces friction during operation. For mass production, pairing with an automatic dipping paint production line improves efficiency and ensures more stable insulation results.

These three methods are summarized from our extensive experience serving global customers. They are simple, practical, and low-cost—implement them, and you’ll see significant improvements in motor noise, energy consumption, and stability.

At this point, many of you may be thinking: “We know the methods, but they’re still difficult to implement in practice. Manual winding can’t meet the requirements, and we’re worried about high costs, incompatibility with our products, and subsequent maintenance issues when replacing equipment.”

In fact, this is the exact problem Zongqi has been helping global customers solve. Many friends in motor production, especially small and medium-sized enterprises, face this dilemma: they want to optimize the winding process, improve motor performance, and capture the global market, but lack professional technical support and can’t find cost-effective automatic equipment. Some opt for imported equipment, which is not only expensive but also comes with slow response times and high costs for subsequent maintenance, commissioning, and spare parts replacement—delaying production schedules.

To be honest, competition in the global motor market is becoming increasingly fierce, and customers have higher and higher requirements for motor performance and stability. Relying solely on manual winding or outdated equipment can no longer keep up with market demands. You invest heavily in high-quality stator cores and enameled wires, only to waste these premium components due to inadequate winding processes. In the end, the motors can’t be sold at a good price, or you even lose orders—which is simply not worth it.

Choosing a suitable automatic stator winding machine not only solves all the pain points of the winding process but also helps you save labor, improve efficiency, and reduce costs. In the long run, it can even help you earn more profits. That’s why more and more global customers are choosing to cooperate with Zongqi.

As a professional manufacturer of automatic stator winding equipment for motors, Zongqi has been deeply rooted in the global market for many years and understands the needs of global customers better than anyone. We don’t produce flashy equipment—only products with strong adaptability, simple operation, and high cost performance. Whether you produce small household appliance motors, industrial motors, or new energy vehicle drive motors, we can customize exclusive winding solutions based on your product specifications and production output.

Compared with other manufacturers, we have three core advantages—these are also the reasons many global customers continue to choose us:

First, high equipment precision and strong adaptability. Our winding equipment offers sufficient precision—whether using thin copper wire or flat copper wire, ordinary winding or segmented winding, it can achieve precise winding to meet the production needs of different motors. Additionally, the equipment supports one-key mold change, making it easy to handle multi-variety, small-batch production without repeated mold commissioning.

Second, fast after-sales response with no worries. Many global customers worry that no one will address issues after purchasing equipment, delaying production. But when cooperating with us, you have nothing to fear—relying on mature remote operation and maintenance technology and an integrated “cloud-edge-terminal” service model, our engineers will respond within 48 hours if there’s an equipment failure, no matter which country you’re in. We’ll quickly resolve the issue through remote guidance and commissioning, and also provide free technical training to teach your employees how to operate and maintain the equipment, so you can use it with complete confidence.

Third, high cost performance to help you control costs. Our equipment is more competitively priced than imported alternatives, yet its performance and quality are in no way inferior. Core components are all well-known brands, ensuring stable trouble-free operation and effectively reducing downtime losses. Furthermore, the equipment is energy-efficient, helping you save on electricity costs. With automatic operation, one machine can replace multiple skilled workers, significantly reducing labor costs and allowing you to recover your equipment investment in a short period of time.

In addition, we provide long-term technical support for cooperative customers—no matter what problems you encounter in optimizing the winding process, whether you want to improve the slot fill rate or solve noise and short-circuit issues, our technical team will provide free solutions to help you continuously optimize your production process, improve motor performance, and make your products more competitive in the global market.

Many global customers who cooperate with us initially had concerns—worried about equipment incompatibility and inadequate after-sales service. But after cooperating with us, they all feedback that choosing Zongqi was the right decision—it not only solved their winding process pain points but also improved motor performance, increased orders, and reduced production costs.

Finally, we want to say this to you: optimizing the stator winding process is not an overnight task, but finding the right methods and equipment can help you avoid many detours. There are many opportunities in the global motor market today, but also great challenges. Only by improving motor performance and controlling production costs can you gain a firm foothold.

If you’re also troubled by the stator winding process, if you want to optimize the process and improve motor performance, or if you’re looking for a cost-effective automatic winding machine, please feel free to contact Zongqi. We’ll customize the most suitable solution based on your actual needs, providing full-process support from equipment selection and commissioning to after-sales maintenance and technical support. Let’s seize the opportunities in the global motor market together and achieve mutual benefit and win-win results.

No matter what questions you have—even if you just want to ask about small tips for the winding process—you can contact us at any time. We’ll reply to you as soon as possible, provide free answers, and offer no promotions or gimmicks—just be your sincere partner.

Post time: Feb-09-2026